GILSONITE ( NATURAL BITUMEN ) Natural Asphalt

When crude oil has been grown and transferred into surface of earth over the millions of years, it was appeared as crystals near the upper surface of the earth. Geographically, this valuable material was discovered for the first time in the Utah region of the United States and also in western Iran in the province of Kermanshah and Ilam.

Our Gilsonite:

Considering the company’s long-term experience in the exploration and extraction of minerals and the production and processing of bitumen from Graveh Mine as the first producer of bitumen, it should be noted that this company is located in Qasr Shirin district of Kermanshah (1953) and powdered bitumen at the size of (-40) mesh was produced for the production of bitumen products including Enamel, Primer and Mastic in a production unit located in Biston in Kermanshah (1961). With the efforts of research and development engineers, this company succeeded in designing, constructing, and installing and initiating 2 Raymond production lines, which resulted in the production of a micronized powder at the size of -200 meshes per year (1991) and a system for reducing moisture and ash in produced powder. Considering the use of the latest technology in bagging and packaging and quality control of production in this area during the seven years, it was selected as the best producer and processor and exporter in the province. In addition, using mechanization system on underground explorations, it was also selected as the main supplier and exporter in the country over the last 15 years. The production capacity of this mineral is currently about 20,000 tons in bulk and 14,000 tons micronized powder per year, most of which are used by bitumen and bitumen membrane roof sheet factories.

How To Order Gilsonite

To order Gilsonite please specify

- How many MT?

- Lump or powder?

- If powder what mesh size?

- Which packing?

- What is the application?

- Where is the destination?

Mode of order

- In to Bulk

- In to powder under 200 mesh

- Sizing in accordance with Client request

Packing Mode

1-Packing in Standards Is one jumbo bag in case of customer’s order packing mode will be into 25 kg laminating bags.

2-Corresponding with customers’ request (belting, palletized and shrink stretch) and it’s has costs at about the original powder price.

Quality of The Goods

1- As attached Analyze. we have 3 Grade IM101 – IM102 – IM103

2- Analysis in accordance with Standards ASTM D482 , ASTM D2042, ASTM D3142, ASTM D3174

3- Sampling and analyzing would be done by SGS In Factory or Bandar Abbas port.

Payment term :

40% by T.T after buyer’s confirmation of P/I and 60% against B/L copy

(Chines customers should refer to our agency in Guangzhou). Further information will announce after contract confirmation

Delivery time

1-As Bulk 100 MT/day basis FOB Bandar Abbas.

2-As Powder 30 MT/day basis FOB Bandar Abbas.

* You can visit our mine and factory in google earth.

Coordinate of our factory (Bistoon)

38 s (IRAN)

34° 22́ 18.96 ً N

47° 25́ 30.58ً E

Coordinate of our mine (Garaveh)

38 s (IRAN)

34° 27́ 46.36 ً N

45° 40́ 58.76ً E

Asphaltite, any of several naturally occurring, hard, solid bitumens whose chief constituents, asphaltenes, have very large molecules. Asphaltites are dark brown to black in colour. They are insoluble in petroleum naphthas and thus require heating to release their petroleum content. Though related to asphalts, asphaltites differ from them chemically and physically in some ways. Asphaltites, for example, usually contain little or no inorganic minerals, but asphalts may have a relatively large percentage of such matter. Also, unlike asphalts, asphaltites do not fuse readily.

Asphaltites are commonly classified into three groups: Gilsonite (or uintaite), glance pitch (or manjak), and grahamite. These substances differ from one another basically in terms of specific gravity and temperature at which they soften.

What is Gilsonite ?

Natural Asphalt ( Natural Bitumen )

Gilsonite could be a natural, adhesive hydrocarbon. This natural asphalt is comparable to arduous petroleum asphalt and is usually referred to as a natural asphalt, asphaltite, uintaite, or asphaltum. gilsonite is soluble in aromatic and aliphatic solvents, also as petroleum asphalt. Because of its distinctive compatibility, gilsonite is usually wanting to harden softer petroleum product. gilsonite in mass could be a shiny, black substance similar in look to the mineral volcanic glass. It’s brittle and might be simply crushed into a dark brown powder.

Gilsonite is found below the Earth’s surface in vertical veins or seams that are usually between 2 and 6 feet in width, however may be as wide as 28 feet. The veins are nearly parallel to every difference and square measure adjusted during a northwest to southeast direction. They extend several miles long and as deep as 1500 feet. The vein can show up on the surface as a skinny stone and bit by bit widen because it goes deeper. Because of the slim mining face, gilsonite is deep-mined nowadays, very like it absolutely was 50 or 100 years past. The first difference is that fashionable miners use gas breaking hammer and mechanical hoists.

Gilsonite history:

The mineral currently recognize as gilsonite was discovered within the early 1860’s, however it absolutely was not till the mid-1880’s that samuel H. Gilson began to promote it as a water-proof coating for picket pilings, as associate degree insulation for wire cable, and as a novel varnish. Gilson’s promotion of the ore was therefore successful that, in 1888, he and a partner shaped the primary company to mine and market gilsonite on an advertisement scale.

Originally, gilsonite was sold as “Selects” and “Fines”; the law softening purpose ore with conchoidal fracture was called “Selects”.

Time and technology have modified this organization. The process of gilsonite currently removes most of the inert contaminants and newer, a lot of powerful, solvents create the upper softening purpose grades a lot of interesting to the user. Today, gilsonite is hierarchal by softening purpose (a rough live of solubility) and particle size. All grades carry a degree of quality, so much superior to those initial little amounts of crude gilsonite marketed within the 1880’s.

Gilsonite Solutions:

Gilsonite is an important element of today’s printing inks, paints & industrial coatings. gilsonite is employed as a tough resin and carbon black dispersant during a type of coatings. Solutions of gilsonite (sometimes referred to as cutbacks or varnishes) are a wonderful start line for blending gilsonite with alternative elements of a final product formulation. Some formulators convert dry gilsonite into liquid answer in their own facilities. Others can request a pre-made solution.

Converting dry, granular gilsonite to a liquid answer also provides the chance to remove the little quantity of abrasive grit that happens in natural asphaltums. stabilising additives may be additional if a poor solvent is employed or if high concentrations of gilsonite are desired.

Gilsonite Solubility:

Gilsonite is soluble in a cyclic, aromatic and chlorinated hydrocarbon solvents. it’s restricted solubility in most ketones, however is soluble in mixed aromatic solvents that contain a organic compound element. gilsonite isn’t soluble in water, alcohols, or acetone.Solution Preparation: 3 basic procedures are accustomed dissolve gilsonite. In every case, precautions for flammable pmaterials ought to be used.

• Cold-cutting: gilsonite is mostly soluble in aliphatic and aromatic solvents at ambient temperatures. Some agitation ought to be used. The rate of solution can rely on the sort of solvent, the sort and severity of blending, and also the grade of gilsonite. The solution rate is increased by employing a high shear mixer, like a Cowles disperser. Once a ball mill or a paddle mixer is employed, lump grade gilsonite is suggested. Once a high energy combination is accessible, either lump or fine grades are also used. Care should be taken to avoid “dry balls” of unmelted solid once using pulverized grades.

• Hot-cutting: the rate of solution is redoubled by heating. Steam coils or hot oil is most popular. Direct-fired heating is venturesome. Care should be taken to avoid or make up for gaseous solvent. Facilities for solvent containment are usually necessary. The utmost process temperature can rely on the boiling vary of the solvent.

• Hot fluxing: gilsoniteis hot fluxed into asphalts and high boiling oils. Once alloyed, the mixture will then be let down with a solvent to succeed in the desired consistency. This hot fluxing with another product will facilitate overcome limitations of solubility. Choosing the right mix or co-solvent will yield compatibility with a solvent that’s ordinarily of restricted solubility.

Gilsonite

Hot Fluxing Procedure: Heat the oil to 200°F or more. Most of the high boiling, law aromatic ink oils in use these days would require a temperature of a minimum of 300-330°F. With smart agitation, add dry gilsonite at a rate that maintains constant dispersion of the particles until they dissolve. Be alert for foaming that may be caused by traces of wet within the gilsonite. Still agitate for 15 to half-hour on the far side the purpose once the last of the gilsonite particles is detected. The gilsonite ought to currently be utterly dissolved and also the solution prepared for discharge.

Filtration: The varnish should be filtered to get rid of the grit that’s a natural part of gilsonite. There are 2 common filtration ways. Every provides a distinct degree of cleanliness. Each ways are commonly preceded by passing the new varnish through a course wire screen (approx. 1/4″) to get rid of any massive stones.

For a standard degree of cleanliness, the prescreened, hot varnish is gone through wire screen baskets of concerning 200 mesh (74 microns). Cloth bag filters may be used, at a better value, once the corporate doesn’t have the personnel to clean the wire baskets. Disposal of the baggage is additionally a thought. Watch out to use baggage that may tolerate elevated temperatures if hot cutting is performed.

For additional cleanliness, the prescreened, hot varnish is gone through cartridge filters of concerning 5 to 25 microns. These filters are also disposable.

• Viscosity Modification:

Some gilsonite solutions are often quite viscous at ambient temperature. also, some solutions will steady increase in consistence over time. These characteristics are typically observed once exploitation law aromatic oils with poor solvent power or once high percentages of gilsonite are used. In these cases, tiny amounts of viscosity modifiers are typically additional to keep the new varnish sufficiently fluid for simple filtration and to cut back and stabilize the close viscosity therefore the answer remains fluid until it’s used.

Gilsonite ( Natural Bitimen) Natural Asphalt

The following could be a partial list of modifiers that are effective at helpful the consistence of gilsonite solutions.

1. Soft asphalt flux. This is often substituted for 15 to 20 make the most the gilsonite within the varnish. At this level, it reduces the softening purpose of the gilsonite by concerning 30°F. It shouldn’t be used once most hardness and rub resistance is desired, or once quick solvent unleash is needed, or once restrictive health safety rules are in effect.

2. Tridecyl alcohol (TDA). A lot of volatile than some modifiers (a flash purpose of 180°F), however effective. Typically used at 3-10%, supported the gilsonite content.

3. Low mass alcohols. Examples are n-propanol and n-butanol. These are effective, however their high volatility typically restricts their use to quick drying systems or merchandise that are keep and used at close temperature.

4. Oil fatty acids. These are chiefly oleic and linoleic acids with little amounts of rosin acids present. They’re used for his or her high flash purpose and law volatility. In some cases, lipid or oleic acid, or vegetable oils like flaxseed or soya bean oil, are often substituted for oil fatty acids with comparable performance.

5. Surfactants. a large sort of industrial surfactants are also effective. Care should be taken to avoid any undesirable side effects on the performance of the final product.

Gilsonite utah could be a black, brittle, lustrous mineral consisting of hydrocarbons, chiefly found within the Southwestern section of the us, principally in utah and Colorado.

Gilsonite especially that found within the utah Basin, Uintah County, State of utah, with a proper proportion of utah Gilsonite, as conjointly found within the Uintah Basin of utah and selected from the standpoint of physical characteristics which will effectively modify such characteristics of the natural tar sand, and that, by fine-sizing both such materials, preferably done therefore together so that the Gilsonite can alter the stickiness of the tar sand and the tar sand can alleviate the Gilsonite dust, a final product is obtained that’s actually superior to trinidad Lake Asphalt as a natural additive composition for modifying a paving asphalt, especially the many kinds of refinery asphalt commonly used for paving purposes.

Gilsonite Usage

Because of its unique chemical and physical properties, Gilsonite has been used in more than 160 products

Gilsonite using as below application:

- 1. Mix with asphalt

- 2. Construction

- 3. Printing ink

- 4. Roofing felt

- 5. Paint and coat

- 6. Cementing

- 7. Oil base drilling

- 8. Foundry

- 9. Foundry sand additive

- 10. Steel creating additives

Gilsonite mines operates as an industrial minerals companies over the world and is the world’s primary miner and processor of uintaite, a variety of asphaltite, a specialty hydrocarbon which many countries markets to industrial customers under its registered trademark name Gilsonite.

gilsonite is a glossy, black, solid naturally occurring hydrocarbon similar in appearance to hard asphalt and is believed to be found in commercial quantities in USA, Iran , Colombia, Argentina and Albania.

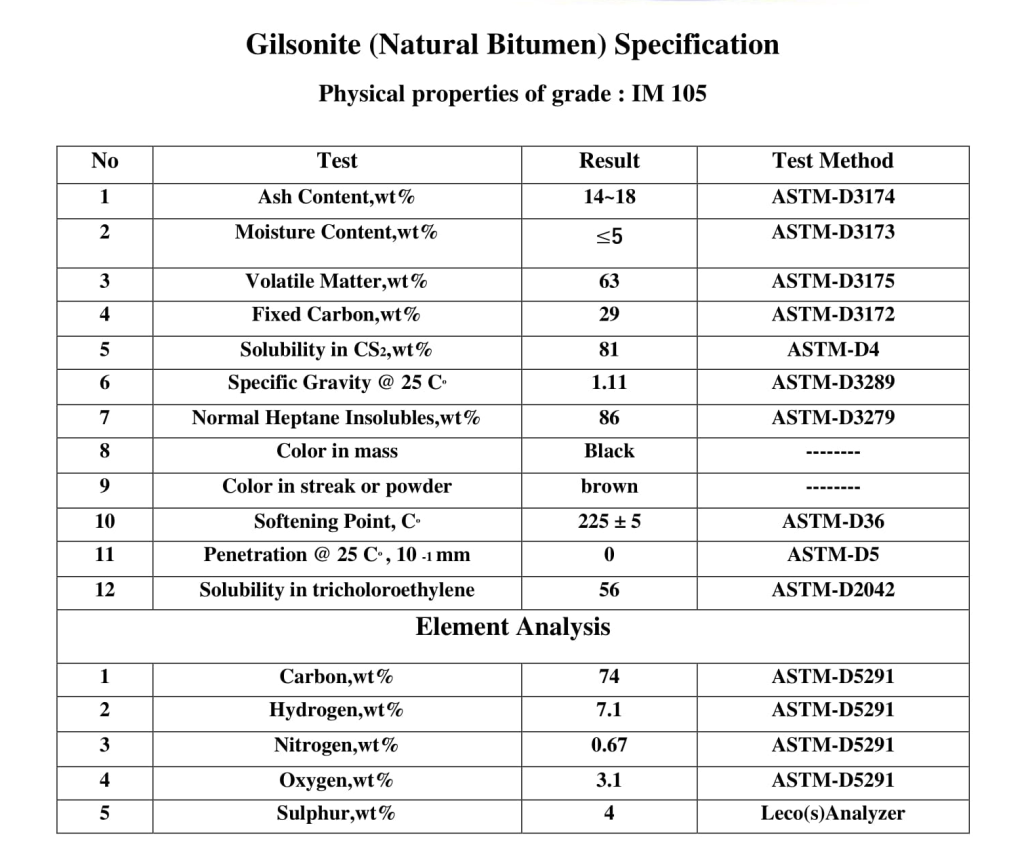

Physical Specification

Gilsonite natural asphalt (asphaltite) additive is a mineral bitumen hydrocarbon in granular form. Its particle size varies between 4- and -200mesh. Pulverized Gilsonite is commonly used to control lost circulation.

It is effective at bottom hole temperatures (BHTs) between 60° and 230°F (16° and 110°C). Typical additive concentrations range from 5- to 50-lb/sk of cement mud.

The low specific gravity of Gilsonite powder helps improve its ability to control lost circulation. However, this feature can also cause the additive to separate to the top of thin slurries and slurries containing dispersants. Adding 2% or more bentonite to the slurry will help prevent separation.

Sieve analysis of Our Gilsonite powder:

Gilsonite Chemical Composition

The environmental granular asphalt which sizes are of 0.1/40MM This recycled granular asphalt is mostly used for new roads layers and finished lines our products are backed by the European union certificates with an SGS report on each shipment.

Primary use

This type of granulate is used for stabilizing roads (second layers) aand also for the first layer,mixed with cement (2%). Bitumen emulsion (2%) or any other binding.

As a result,the roads can be constructed at less cost and these roads are less harmful to the environment and much more durable.

Product details asphalt granular

We sell asphalt granular 0.1/40 also known as bitumen asphalt.our prroducts has oeso international disposal code; GG 160 and eural code.170302

Chemical composition (pak)50 benzo (A)pyreen (confirmed by evoa) this asphalt granular is a green-list disposal composition product.

Gilsonite General Solubility

Gilsonite products is readily soluble without heating in aromatic solvents (Benzene, Toluene, Xylene) and in most chlorinated solvents.

It also soluble without heating in Aliphatic and low aromatic solvents (VM&P and other Naphtha, Ink Oils and Mineral Spirits), but Mixing time is longer. Without heating, the pulverized grade is recommended. Gilsonite has limited solubility in most alcohols and ketones.

Gilsonite Friendly to Water

Water-based Gilsonite is natural bitumen environmentally safe and specially formulated to protect hole shale water base drilling.

The drilling fluid serves a number of functions including taking heat away from the drill bit and facilitating the return of drill cuttings to the surface. There are three main types of drilling mud, including Gilsonite muds.

The present invention deals with the consequences of using water-based drilling Gilsonite muds. When the hydrostatic pressure of the drilling mud in the wellbore exceeds the inwardly acting pressure of the surrounding formation, the drilling mud is forced into the surrounding formation through the walls of the wellbore.

In many applications the drilling Gilsonite mud is intended to be deposited in and/or on the wellbore wall, forming so called “filter cake” which, amongst other things, helps to limit the invasion of formation fluids into the wellbore; reduces the risk of the wellbore collapsing during drilling; and resists the escape of drilling fluids into the formation.

Chemical Specification

Gilsonite or natural asphalt is available to deliver in various grades and categorized by softening point. Softening point is working as an approximate guide to melt viscosity in solution.

The chemical specifications are different between Gilsonite grades, with only solubility and asphaltene resin-oil ratios.

We have 3 grade gilsonite (IM 101,102,103) you can find in the attachment (pdf format)

Gilsonite ( Natural Bitumen ) Specification of Sormak mining Co.

Physical Properties of the Gilsonite Grade: IM 103

Gilsonite Lab

Sormak minig Company is ion vendor of research institute of petroleum industry which is belonging to minister of Petroleum.

There are many national and international specifications and tests stipulated by various authorities, contracts and building regulations around the world. we try to offer as many as we can, while accepting that we cannot offer all things to all of our stakeholders everywhere, given the limited volumes per location. We offer:

Analysis of commercial bulk Gilsonite to ASTM, ISO, EN and similar specifications

Analysis of the basic Gilsonite performance such as:

Penetration numbers

- Ash content

- Moisture Content

- Hardness

- Density

- Solobility in CS2,

- Solobility in Trichloethylene

Storage monitoring to assess oxidation state

Testing of packing Gilsonite over time to asses batch lifetime

QUALITY PROGRAM

All testing laboratories participate in an international proficiency test scheme for Gilsonite. These round robin tests act as a performance indicator and help to maintain a consistently high level of quality and assurance from our labs.

Sormak mining Company inspections Gilsonite cargoes are carried out on the basis of accepted petroleum and petrochemical standards such as ASTM, GOST, API, MPMS, UOP, IP or EN testing methods and specifications as set out by ISO, CEN or national and regional standards-setting organizations.

How you can check ash of gilsonite

The term mineral matter refers to the inorganic constituents of coal and is all of the elements that are not part of the organic coal substance (carbon, hydrogen, nitrogen, oxygen, and sulfur). The mineral matter is the principal source of the elements that make up the ash when the coal is burned in air or oxygen. Four of the five elements generally considered to be organic (carbon, hydrogen, oxygen, and sulfur) are also present in inorganic combination in coals.

Comments Off on Gilsonite (Natural Bitumen) With969Visit