Our Iron Our

The ironstone produced by Sormak Company is in the hematite form and is extracted from the Malayer Ahangaran Mine and it is very suitable for using in cement industries. For this purpose, the produced ironstone is presented in two ranges (0-40mm) and (300-300mm). Over the past 30 years, more than 25 major cement producers in Iran are main purchasers of Sarmak Mine Company ironstone. Sarmak Mine Company ironstone is a low-grade hematite type and it is used solely by cement industry in Iran. The production procedure is such that the hunks are explored and extracted from the mine with the great efforts of the experienced workers and technical experts in the field of geology. Spending time and money, it is extracted from Ahangran mine located near the city of Malayer in Hamedan province directly. After being crushed, it is directly supplied to the market, which this activity has created job for over 200 hardworking personnel and the employment for about 100 truck drivers for transportation to the cement factories. We achieved this goal with the power of the Almighty God and relying on efforts of sympathetic managers and hardworking personnel and using technical and engineering knowledge. The definitive reserve of iron ore in Ahangaran mine, which is mostly of hematite type, is about 11 million tons with an average grade of 35%, from which 500,000 tons can be extracted annually.

What is Iron Ore?

Ironstone is a mineral that contains iron metal. The chemical symbol of iron is Fe. Ironstone is extracted from ironstone mines. The ironstone available in different mines varies in terms of appearance and interior construction. Ironstones are composed of different minerals, but most important are magnetite and hematite

Iron Ore is the most important raw material for the production of iron and steel. In general, the major part of Iron Ore is used in traditional method of production of iron and steel (furnace / converter) and only a part of it is used in other methods, especially direct reduction, so that out of total amount of ironstone extracted in the world, less than 10% of it is used for direct reduction and more than 90% of it is used in long furnaces.

The application of ironstone for the production of iron and steel is one of the following forms:

Granulated Iron Ore

Granulated Iron Ore is today less commonly used. The reason for this can be justified by its low restoration property. However, to use ironstone directly for the production of iron, its dimensions must be well-defined.

Iron Ore as Lump

Hunk(Lump) is the most common method of using ironstone. About 700 million tons of hunks are produced annually and used in the iron and steel industry

Iron Ore as pellet

The pellet production is currently about 300 million tons per year, of which more than 80 precent is used in long furnaces, and the rest of it is used in direct reduction. It is clear that the pellet characteristics are different in each of the method.

What is Iron Ore?

Iron (Fe) is one of the most abundant rock-forming elements, constituting about 5% of the Earth’s crust. It is the fourth most abundant element after oxygen, silicon and aluminium and, after aluminium, the most abundant and widely distributed metal. Iron is indispensable to modern civilisation and people have been skilled in its use for more than 3,000 years. However, its use only became widespread in the 14th century, when smelting furnaces (the forerunner of blast furnaces) began to replace forges.

Iron ores are rocks from which metallic iron can be economically extracted. These rocks are usually found in the form of hematite (Fe2O3) or magnetite (Fe3O4). About 98% of world iron ore production is used to make iron in the form of steel.

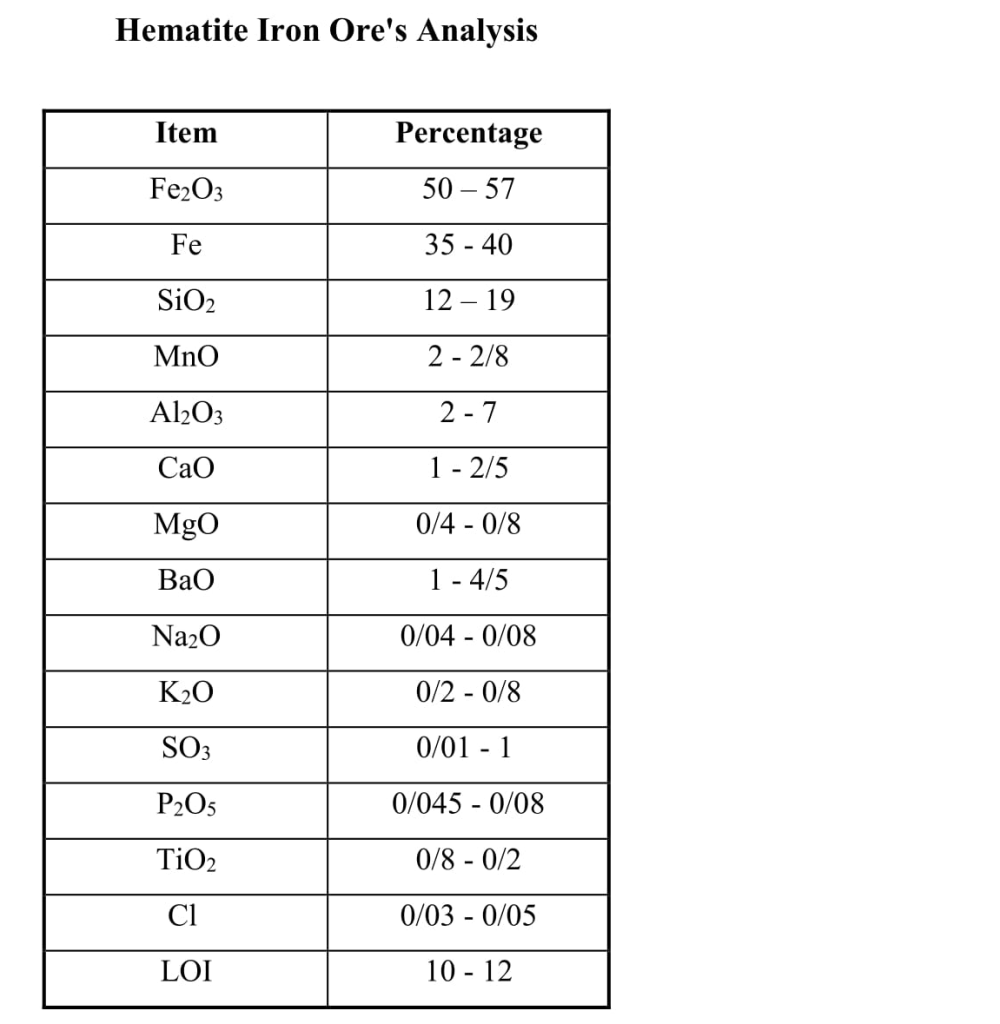

Hematite Iron Ore Analysis:

Comments Off on Iron Ore With1051Visit